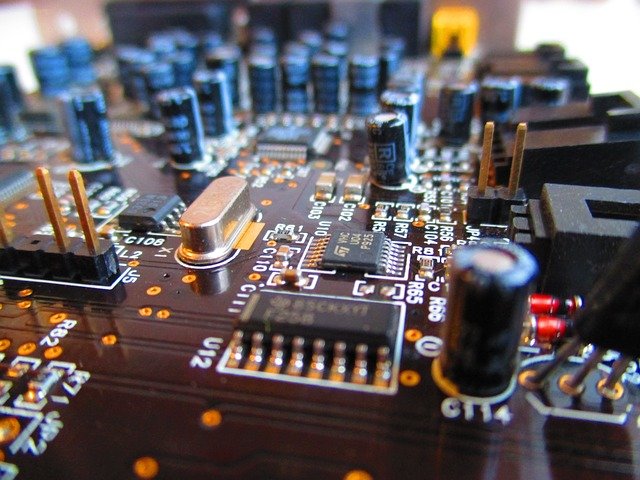

There is a printed circuit board in almost every electronic gadget. This way, a PCB can be called the carrier of electronic devices. You can find PCBs in your computers, household appliances, automotive, and electronic devices.

Printed Circuit Boards are indispensable. So, you might be wondering what the significant material used for the manufacturing of PCBs is. PCBs look very complicated, but they are not very difficult to understand because of their essential material for manufacturing. Hence, in this article, we are going to discuss some common types of materials that are used for producing printed circuit boards. Let’s look at them!

- Substrate

The basic material used for creating printed circuit boards is called copper-clad substrate, also termed the substrate. Generally, the substrate contains a resin plate in which copper is used on both sides.

The widespread plate number utilized in electronic products is FR-4. This plate is majorly found in electronic items like computers and other communication equipment. Flame resistance, TG value, and dielectric constant are required for laminate.

- Copper Foil

The second important material is copper wire that works as a conductor that is used for creating wire on the substrate. Furthermore, copper foil is created with the help of two different manufacturing processes that are electrolysis and calendering.

- PP

The most important material used in the production of printed circuit boards is PP. This material works as an adhesive between the layers. Or simply, you can say that the substrate sheet at stage B is called PP. The main characteristics of PP are the resin (amount of glue) and thickness.

- Dry Film

The photosensitive dry film used in these printed circuit boards is also referred to as a dry film. The major component of the dry film is the resin substance. As it is sensitive to a specific spectrum, so it undergoes a photochemical reaction.

Normally, the dry film consists of three layers, and the middle layer is of photosensitive material that is sandwiched between the upper layer and the lower layer for protection purposes.

- Solder Resist Ink

Solder resist is also known as the solder mask. It is an essential liquid that is made of photosensitive material, and it does not have relativeness for liquid solder. Like the dry film, this ink will also change its form and become harden because of the light irradiation of a particular spectrum.

However, before usage, the solder resists paint requires a hardener to be mixed in it. The colors of these circuit boards are due to the colors of these solder masks.

The Final Words:

Understanding printed circuit boards is not so difficult if you know about the common materials used in PCB manufacturing. Above we have discussed some common materials used for the production of PCBs. Nevertheless, for creating a quality PCB, you should look for a reliable Flexi PCB manufacturer.